In modern agriculture, achieving high yields year-round in commercial greenhouses relies heavily on controlling the internal climate. This regulation creates an optimal growing environment for crops. Greenhouse screens play a vital role in this process, and they can be applied to the interior ceiling, the exterior roof, and the interior sidewalls of greenhouses. They help regulate light, temperature, and humidity while protecting crops from pests. This combination of factors provides ideal conditions for plant growth.

Greenhouse Internal Shading Curtains

Did you know there are various types of screens, each designed for specific functions? In this post, we’ll explore greenhouse screens’ types, features, and uses in commercial greenhouses. This will help you choose your greenhouse’s materials and screen types.

Who we are? Go to explore more about INSONSHADE >

Summary Table: 8 Types of Greenhouse Screens

The table below summarizes the main features of the greenhouse screens we are introducing to help you quickly understand them. These screens are installed in different locations within the greenhouse and work in conjunction with curtain systems.

| Type | Main Function | Shading Rate Range | Energy Saving Rate Range | Application Location |

| Aluminum Shade & Energy-Saving Screens | Shading, Energy Saving | 55%-99% | 20%-70% | Internal Horizontal screens |

| Black & White Reflective Shade Screens | Shading | 65%-99% | 20%-35% | Exterior roof and sidewalls |

| Aluminum Reflective Shade Screens | Shading, Cooling | 65%-99% | 20%-40% | Exterior roof and sidewalls |

| Light-Diffuse Shade Screens | Light Diffusion, Shading | 50%-70% | 45%-49% | Interior ceiling and sidewalls |

| High-Transparency Energy-Saving Screens | Light Transmission, Energy Saving | 10% | 45% | Interior ceiling and sidewalls |

| Flame-Retardant Blackout Curtains | Light Blocking, Flame-Retardant | 99% | 70% | Interior ceiling and sidewalls |

| Non-Flame-Retardant Blackout Curtains | Light Blocking, Energy Saving | 99% | 75% | Interior ceiling and sidewalls |

| Insect/Bird Screen | Pest Control | N/A | N/A | Ventilation points (windows, doors, side openings) |

Type 1: Aluminum Shade & Energy-Saving Screens (Interior)

Aluminum shade & energy-saving screens are typically used on interior ceilings and work by reflecting and diffusing sunlight to maintain a suitable crop temperature. This reflective and diffusive function mainly comes from their aluminum material.

These screens suit various greenhouse interior curtain systems, including hanging and pull-down types. Depending on different application needs, these screens come in various materials and styles. Energy savings range from 20% to 70%, and shading rates range from 55% to 95%. The materials mainly include all-aluminum foil and aluminum foil mixed with polyester. Naturally, the higher the aluminum content, the better the shading rate and energy-saving effect. However, you should choose the right screen combination based on the specific conditions of your greenhouse crops.

Aluminum Shade & Energy-Saving Screen Products by INSONSHADE

Here, we list several commonly used aluminum shade & energy-saving screen types to help you better understand the impact of the aluminum foil and polyester combination on shading rate and energy efficiency:

| Type | Shading Rate | Energy Saving | Materials |

|---|---|---|---|

| All-Aluminum Foil Screen | 99% | 82% | Aluminum foil, polyester |

| 5 Aluminum Foil, 1 Transparent Screen | 95% | 77% | Polyester, aluminum foil, polyester thread |

| 4 Aluminum Foil, 1 Transparent Screen | 85% | 72% | Polyester, aluminum foil, polyester thread |

| 3 Aluminum Foil, 1 Transparent Screen | 75% | 67% | Polyester, aluminum foil, polyester thread |

| 2 Aluminum Foil, 1 Transparent Screen | 65% | 62% | Polyester, aluminum foil, polyester thread |

| 1 Aluminum Foil, 1 Transparent Screen | 55% | 57% | Polyester, aluminum foil, polyester thread |

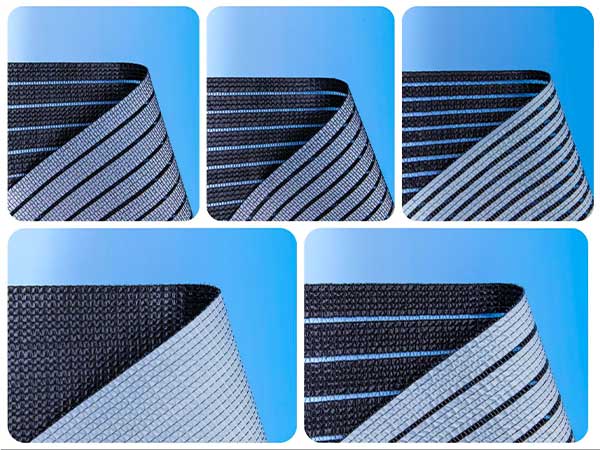

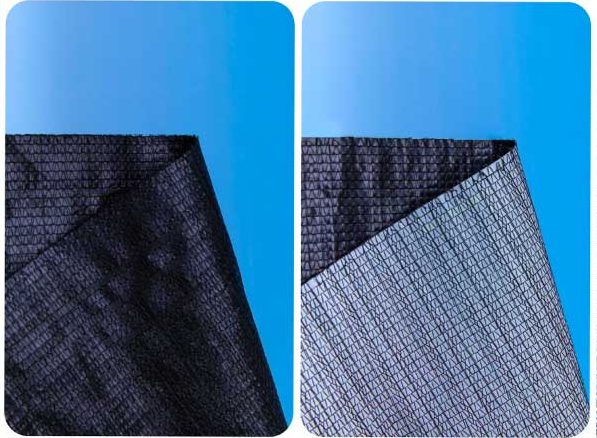

Type 2: Black & White Reflective Shade Screens (Exterior)

Black-and-white reflective shade screens are primarily used on the exterior of commercial greenhouses. They are suitable for roll-up and pull-down systems and focus mainly on providing shade. These screens can be used with interior screens to meet the various climate needs of greenhouse crops.

Made primarily of polyethylene, this kind of greenhouse climate screen is highly durable and effective. It provides shading rates from 65% to 99% and offers some energy-saving benefits, though not as significant as dedicated shade and energy-saving screens, with energy-saving rates ranging from 20% to 35%.

Black & White Reflective Shade Screens (Exterior)

Here are some common specifications of black and white shade screens.

| Weave Type | Shading Rate | Energy Saving | Materials |

| 2 Black & White Films, 1 Opening | 65% | 20% | Polyethylene |

| 3 Black & White Films, 1 Opening | 75% | 25% | Polyethylene |

| 4 Black & White Films, 1 Opening | 85% | 28% | Polyethylene |

| 5 Black & White Films, 1 Opening | 95% | 31% | Polyethylene |

| All Black & White Films | 99% | 35% | Polyethylene |

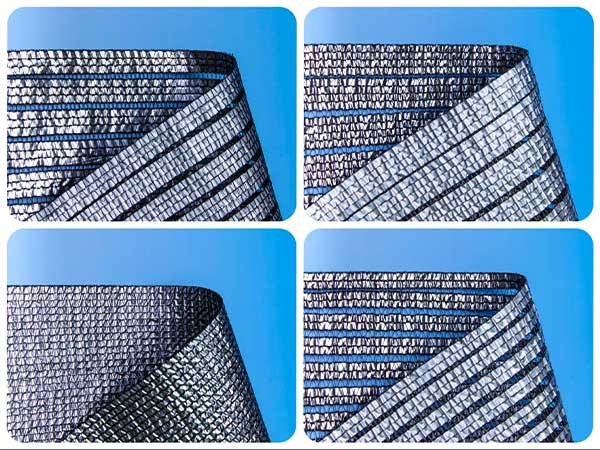

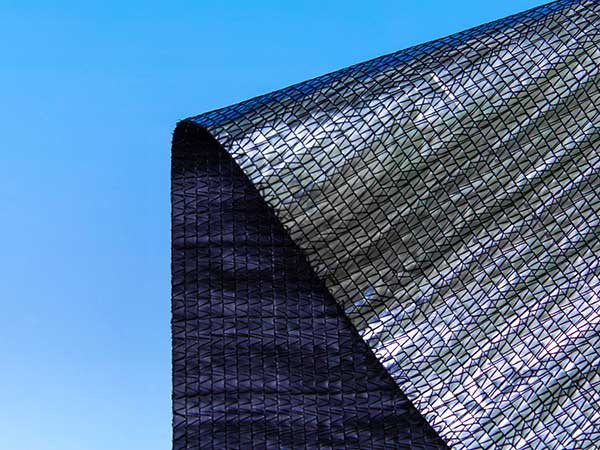

Type 3: Aluminum Reflective Shade Screens (Exterior)

Like black-and-white reflective shade screens, aluminum reflective shade screens are primarily used as curtains for greenhouse exterior shade systems. Made mainly of aluminum foil and polyethylene, they are highly durable and perform well. The properties of aluminum provide a more uniform growing environment for crops.

Aluminum Reflective Shade Screens (Exterior)

Here are some common specifications of aluminum reflective shade screens. You can compare them with black and white reflective shade screens:

| Weave Type | Shading Rate on Sunny Days | Energy Saving | Materials |

| 2 Aluminum Foils, 1 Opening | 65% | 20% | Aluminum foil, polyethylene |

| 3 Aluminum Foils, 1 Opening | 75% | 25% | Aluminum foil, polyethylene |

| 4 Aluminum Foils, 1 Opening | 85% | 32% | Aluminum foil, polyethylene |

| All Aluminum Foil | 99% | 40% | Aluminum foil, polyethylene |

Choosing between black and white or aluminum reflective shade screens depends on the conditions of your greenhouse and crop needs. Black and white reflective shade screens use polyethylene, with the black part absorbing heat and the white part reflecting heat, providing balanced heat management. Aluminum reflective shade screens excel in light diffusion and daytime cooling but may not control nighttime temperatures as effectively as black and white screens. Black and white reflective screens might be more suitable if your greenhouse crops need shading and heat retention. However, aluminum reflective screens might be better if your greenhouse is in a region with extreme heat or your crops require shading and cooling.

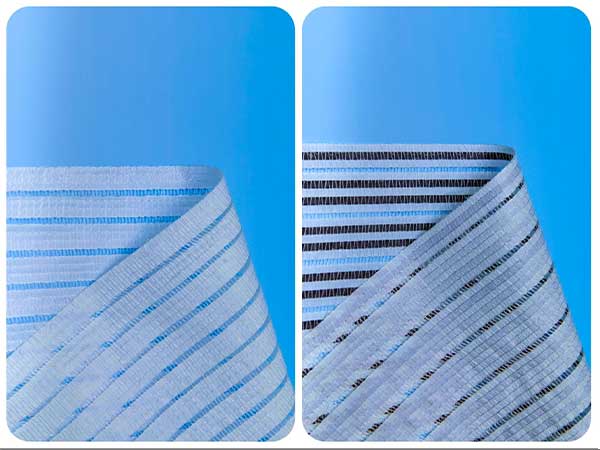

Type 4: Light-Diffuse Shade Screens (Interior)

As the name suggests, light-diffuse shade screens are mainly used for scattering light and shading. They are suitable for hanging and pull-down systems inside greenhouses. Made primarily of polyester and polyester thread, these screens convert direct sunlight into diffuse light, allowing light to reach all parts of the crops evenly and gently. This improves the greenhouse’s light environment and temperature distribution, creating a suitable crop environment and enhancing their quality and yield.

Light-Diffuse Shade Screens (Interior) – INSONSHADE

Here are two common specifications of light-diffuse shade screens. The density between the film and openings affects the shading rate, helping you choose the right light-diffuse shade screen for your greenhouse crops in the future:

| Type | Shading Rate on Sunny Days | Energy Saving | Materials |

| 1 White Diffuse, 1 Black & White Film, 1 Opening | 70% | 49% | Polyester, polyester thread |

| 3 White Diffuse, 1 Opening | 50% | 45% | Polyester, polyester thread |

At this point, you might confuse light-diffuse shade screens with shade and energy-saving screens. While both types have light diffusion and scattering functions, they differ significantly in design goals, functional focus, materials and structure, and application scenarios. Here’s a simple comparison to help you distinguish between them:

| Comparison Item | Shade & Energy-Saving Screens | Light-Diffuse Shade Screens |

| Design Goal | Reduce energy consumption through sunlight reflection and insulation, improving overall energy efficiency in the greenhouse. | Provide even lighting and prevent scorching, improving the crop-growing environment. |

| Functional Focus | Heat management by reducing heat entry and retaining warmth to save energy. | Uniform light distribution and optimizing the greenhouse’s light environment. |

| Materials and Structure | Use aluminum foil and highly reflective materials, emphasizing reflection and insulation. | Use polyester and polyester thread, emphasizing light diffusion. |

| Application Scenarios | It is suitable for greenhouses that need energy savings and temperature control, such as those requiring strict temperature management for vegetables and flowers. | It is suitable for crops needing even lighting and scorch prevention, such as greenhouse vegetables, flowers, and especially seedlings. |

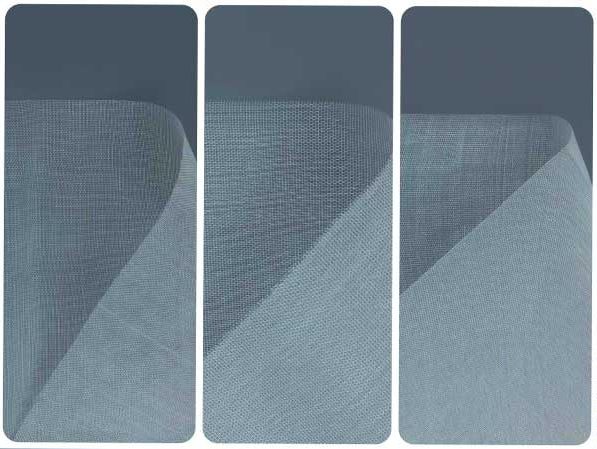

Type 5: High-Transparency Energy-Saving Screens (Interior)

Transparency screens are mainly used inside greenhouses and are made primarily of polyester and polyester thread. They are almost completely transparent. The material allows for excellent light transmission and condensation absorption, with some energy-saving effects. Common high-transparency energy-saving screens have a shading rate of 10% and an energy-saving rate of about 45%. These screens provide maximum daylight during the day and reduce condensation damage to greenhouse crops at night. They are suitable for crops requiring light,

High-Transparency Energy-Saving Screens – INSONSHADE

Type 6: Flame-Retardant Blackout Curtains (Interior)

These blackout curtains are designed to control the photoperiod by blocking and limiting light entry and diffusion, helping regulate the day and night length for light-sensitive greenhouse crops. These curtains are used indoors and are made from polyethylene and polyester thread, treated to be flame-retardant. They are suitable for hanging and pull-down systems, effectively controlling the photoperiod of greenhouse crops and providing some cooling effect.

Two common types are available: flame-retardant black-and-white and all-black blackout curtains. The black-and-white curtains combine black and white surfaces, with the black part used to block light and the white part to reflect light. The all-black blackout curtains are made entirely of black material, completely blocking light.

Flame-Retardant Blackout Curtains (Interior) – INSONSHADE

Here is a comparison to help you understand their similarities and differences, making it easier to determine which is more suitable for your greenhouse crops:

| Comparison Item | Flame-Retardant Black & White Blackout Curtains | Flame-Retardant All-Black Blackout Curtains |

| Materials | Polyethylene, polyester thread | Polyethylene, polyester thread |

| Flame Retardant | Yes | Yes |

| Shading Rate on Sunny Days | 99% | 99% |

| Energy Saving | 70% | 70% |

| Function | Blocking light, limiting light, energy-saving | Blocking light, limiting light, energy-saving |

| Humidity Control | Good | Good |

| Style | Black and white film | All black film |

| Reflective Effect | Reflective material on top surface, good cooling | No reflective material blocks light with black material |

| Light Control Ability | Excellent at controlling light diffusion, reducing the impact on adjacent facilities and crops | Completely blocks light, suitable for environments requiring strict light control |

| Enhanced Artificial Lighting Effect | Yes | Yes |

| Application Scenarios | Suitable for crops needing photoperiod control and cooling, such as chrysanthemums, tomatoes | Suitable for crops requiring strict photoperiod control, such as cannabis, ginseng |

Type 7: Non-Flame-Retardant Blackout Curtains (Interior)

Common types of non-flame-retardant blackout curtains include all-black and aluminum-faced blackout curtains. Due to the unique properties of aluminum-faced screens, we will focus on this type. Made of polyethylene, aluminum foil, and polyester thread, aluminum-faced blackout curtains are suitable for hanging and pull-down systems. They have a shading rate of up to 99% and an energy-saving rate of up to 75%. The aluminum foil layer provides higher reflectivity and energy efficiency, making it ideal for greenhouse crops that require high light management and efficient cooling.

Non-Flame-Retardant Blackout Curtains (Interior) – INSONSHADE

The main difference between flame-retardant and non-flame-retardant blackout curtains is the presence of flame-retardant materials. Despite lacking flame retardancy, the aluminum foil layer of non-flame-retardant screens offers higher reflectivity and energy efficiency, making them suitable for crops that need high light management and effective cooling.

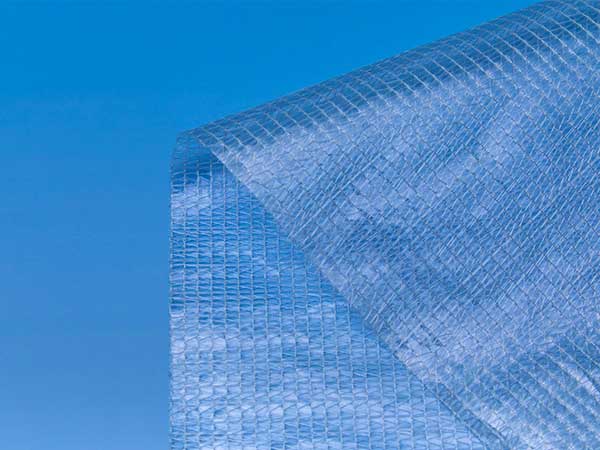

Type 8: Insect/Bird Screen (Ventilation)

Insect/bird netting is a specially designed mesh to prevent pests and birds from entering greenhouses. Made of high-strength polyethylene or polypropylene, it features a dense mesh structure that acts as a physical barrier, keeping pests out and protecting crops from infestations. Typically installed at ventilation points such as windows, doors, or side openings, and sometimes on the roof, this netting helps reduce pesticide use, mitigates wind effects on greenhouse temperature, stabilizes the growing environment, and improves crop quality and yield.

Insect / Bird Screen (Ventilation) – INSONSHADE

Conclusion

In conclusion, various climate screens play different roles in optimizing the internal environment of commercial greenhouses. Shade and energy-saving screens, black and white, and aluminum reflective screens mainly regulate light and temperature and are suitable for different greenhouse conditions. Light-diffuse screens improve the light environment, high-transparency energy-saving screens provide maximum light, flame-retardant and non-flame-retardant blackout curtains control the photoperiod, and insect/bird netting protects crops through physical barriers.

Choosing the right screen depends on your needs to enhance greenhouse crop growth efficiency and quality effectively. As a professional shade cloth manufacturer, INSONSHADE can provide expert advice for selecting climate screens for commercial greenhouses. Contact us now, and we will respond promptly.