Commercial greenhouses can provide significant advantages for large-scale farming: from precise climate control and extended growing seasons to enhanced crop yields. Yet, the initial investment and ongoing operational costs of a commercial greenhouse are often a major concern for growers.

This guide will explain the key cost factors, provide a commercial greenhouse cost calculator, and highlight specific references for a 10,000 sq ft greenhouse cost. Understanding these components will better equip you to determine a realistic budget and make an informed decision about the greenhouse type and scale most suitable for your operation.

Don’t Miss: Best Commercial Greenhouse Manufacturers Worldwide

Average Cost Range of a Commercial Greenhouse

Commercial greenhouse costs can vary significantly based on size, location, design complexity, and materials used. Generally, you might see typical costs ranging from $15 to $35 per square foot. However, more advanced or specialized structures can exceed this range.

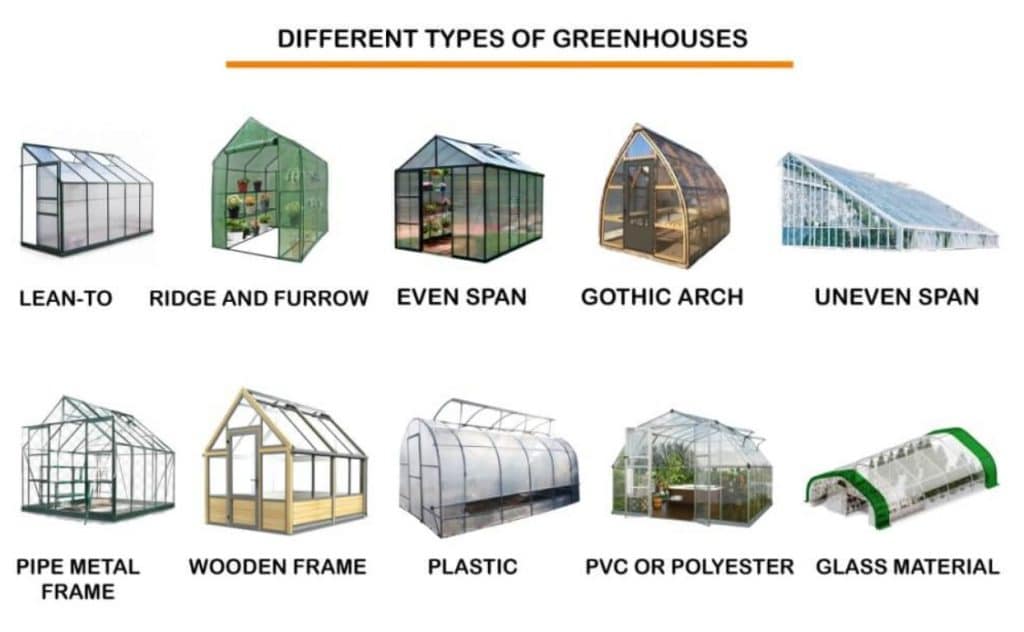

Greenhouse Type Impacts Its Cost – ourendangerdworld.com

Here are the average costs for different types of commercial greenhouses, and you can easily calculate the cost of a 10,000 sq ft commercial greenhouse using the calculator below.

For instance, a standard 10,000 sq ft commercial greenhouse usually runs between $150,000 and $350,000, roughly $15 – $35 per sq ft. If you opt for high-end systems – such as automated climate control, hydroponic facilities, or advanced shading – you could easily exceed the upper limit, potentially reaching $400,000 or more.

10,000 Sq Ft Greenhouse Cost: A Closer Look

A 10,000 sq ft greenhouse is a popular size for many commercial growers. Here’s a quick breakdown of typical cost scenarios:

1. Basic Configuration: $20–$30 per sq ft

Estimated Total: $200,000–$300,000

Often includes a steel or metal frame, basic covering (polycarbonate or plastic film), standard ventilation, and minimal automation.

2. Advanced or High-End Configuration: $40+ per sq ft

Estimated Total: $400,000+

May include glass or high-quality polycarbonate covering, automated shading, climate control systems (heating, cooling, humidity control), advanced irrigation/hydroponic setups, and computerized monitoring.

These numbers serve as a guideline. Actual costs can be higher or lower depending on regional labor rates, specific design needs, and the level of environmental control desired.

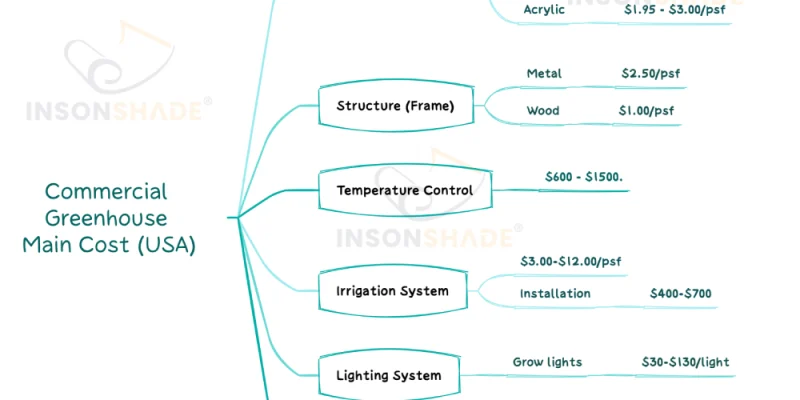

10 Cost Factors for Commercial Greenhouses

Below is a concise table reflecting the 10 key cost factors for a commercial greenhouse project in the U.S., styled similarly to the article above. Adjust percentages and price ranges based on local conditions and project specifics.

| Key Factor | Approx. % of Total Cost | Typical US Price Range | Description |

|---|---|---|---|

| 1. Civil Engineering | 20%–30% | $2–$6/sq ft (groundwork) | – Includes foundation, site grading, drainage, and essential utilities (electricity/water). – Costs can vary significantly based on soil conditions and climate requirements. |

| 2. Steel Framework | 15%–20% | $2.50–$3.60/sq ft (by area) $1.50–$6.75/linear ft (material) |

– Core structural supports (columns, beams, arches). – Material choice (galvanized steel, aluminum, etc.) and design complexity influence the final price. |

| 3. Covering Materials | 20%–30% | – Glass: $2.50–$3.50/sq ft – Polycarbonate: $1.50–$3.00/sq ft – Plastic Film: $0.10–$0.70/sq ft |

– Determines light transmission, insulation, and durability. – Glass offers high clarity but costs more; polycarbonate balances insulation and strength; film is cheaper but has a shorter lifespan. |

| 4. Shading Systems | 10%–15% | $1.00–$1.50/sq ft | – Internal/external shade cloth plus the mechanical system. – Reduces excessive light and heat, improving crop quality and energy efficiency. |

| 5. Cooling Systems | 15%–20% | $2.00/sq ft (comprehensive setup) | – Commonly uses evaporative cooling pads, fans, misting, or fog systems. – Essential for hot climates or summer months to maintain optimal temperatures. |

| 6. Ventilation Systems | 10%–15% | $2.50/sq ft (advanced systems) Exhaust fans: ~$125 each |

– Includes roof vents, side vents, exhaust fans, or automated louvers. – Proper airflow regulates humidity and temperature within the greenhouse. |

| 7. Installation & Transportation | 5%–20% | Varies by region, distance, and material volume | – Covers freight charges, on-site labor, equipment rentals, and crane services. – Greater distance or larger structures can drive up logistics costs. |

| 8. Energy Consumption | – | Dependent on local utility rates & system design | – Includes heating, cooling, and supplemental lighting (e.g., LED grow lights). – Colder or hotter regions require more robust HVAC solutions. |

| 9. Maintenance & Repairs | ~3%–5% of total investment (annually) | Project-specific | – Routine cleaning, equipment servicing, and covering replacements. – Proactive maintenance can extend system lifespan and reduce major repair costs. |

| 10. Labor Costs | – | $15–$25/hr (agricultural roles); higher for management | – Encompasses greenhouse management, crop cultivation, and general upkeep. – Labor needs vary based on greenhouse size, automation level, and crop complexity. |

Note: The ranges above serve as general guidelines for U.S. markets. Actual figures will differ depending on location, design complexity, material quality, and automation level. Always include contingency funds to cover unexpected site conditions or regulatory requirements.

Commercial Greenhouse Cost Calculator

A simplified way to estimate your greenhouse’s total cost is to break down the major spending categories. A helpful formula often looks like this:

Total Cost = Construction Materials Cost + Site Preparation and Equipment Costs + Labor Costs + Contingencies

- Construction Materials Cost: Includes steel or aluminum framing, covering materials (glass/polycarbonate/film), shading, ventilation, etc.

- Site Preparation & Equipment: Grading, leveling, drainage, irrigation, climate control, and any specialized equipment (e.g., hydroponic systems).

- Labor Costs: On-site installation, technical staff, transport, and logistical labor.

- Contingencies: Permits, unexpected ground conditions, engineering adjustments—any “unforeseen” expenses.

Example Calculation for 10,000 sq ft

Let’s assume a basic configuration at $25 per sq ft (a mid-range estimate):

- Construction Materials: $15 per sq ft → $150,000 total

- Site Prep & Equipment: $5 per sq ft → $50,000 total

- Labor: $3 per sq ft → $30,000 total

- Contingencies: $2 per sq ft → $20,000 total

Total Estimated Cost = $150,000 + $50,000 + $30,000 + $20,000 = $250,000

This is just a sample. Adjust each component based on your design complexity, local labor rates, and material prices.

Conclusion

Building a commercial greenhouse—whether it’s a modest 10,000 sq ft unit or a multi-acre complex—is a substantial investment that can greatly enhance your growing capacity and yield. By understanding the key factors influencing costs—from civil engineering and materials to labor and energy—you can more accurately plan your budget and avoid unpleasant surprises.

Use the commercial greenhouse cost calculator framework provided here to assemble a realistic estimate, and always account for ongoing operation and maintenance expenses in your financial planning. A commercial greenhouse can become a highly profitable extension of your agricultural endeavors with careful research and strategic planning.

If you are considering your own commercial greenhouse project, be sure to explore reputable manufacturers, consult with local experts for site-specific guidance, and build a system that balances upfront capital, long-term sustainability, and year-round production efficiency.